PCB Assemblers Are Used in Which Industries

PCB assembly is the process of mounting small components onto a circuit board in order to ensure that it functions in a certain way. As such, pcb assemblers play a critical role in ensuring that the electronics produced by various industries meet their intended design specifications. In addition to performing assembly duties, a pcb assembler can also troubleshoot any issues with the product and make changes to machinery settings accordingly. They may also conduct quality inspections and receive feedback from supervisors or managers on their work.

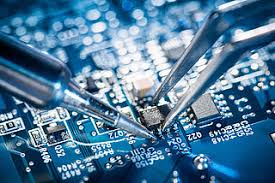

Whether working manually or with automated equipment, a pcb assembler will first place the copper tracks that will form the basis for the entire circuit board’s electrical connections. Then, they will use a stencil printer to apply solder paste in areas where components need to be placed. A machine known as a pick and place will then automatically pick up and apply these tiny components onto the board, which is then passed over a heating device to melt the paste and essentially lock the component in its position on the surface of the PCB.

Assemblers can choose between two main types of pcb assembler: through-hole mount and surface mount technology. Some circuit boards require a mix of both, which requires special consideration in the layout phase. This helps to reduce the number of components required for the finished product, which in turn lowers manufacturing costs.

How PCB Assemblers Are Used in Which Industries

Through-hole mounting involves placing the component leads into holes that have been drilled into a bare PCB. It’s an older technology that creates a stronger connection than surface mount because the leads go all the way through the board. However, it can be difficult to work with and requires more time.

With the introduction of newer technologies like surface mount components (SMCs), the pcb assembly industry has become much more efficient. SMCs are much smaller than the through-hole components that are used in older boards, making it impractical to hand place them. As a result, pcb assemblers now use programmable auto-inserting machines to mount these miniature components. These machines have the necessary SMCs lined up in reels, and the pcb assembler simply needs to program the machine to pick up a specific component from the reel and place it at a point on the board where they have already deposited glue or solder paste.

Regardless of the type of PCB assembly needed, the pcb assembler must be able to handle various materials and machinery, including power tools and other heavy machinery. They must also follow strict safety guidelines to avoid any accidents or injuries during the manufacturing process. Assemblers should be able to read and understand detailed schematic diagrams, as well as communicate with other workers in their team. In addition, they must be able to follow instructions from supervisors and managers regarding the production of the product.